Among heavy machinery, skid steer loaders are really workhorses. Builders, landscapers, agricultural laborers, and do-it-yourselfers all depend on their tiny size, fast agility, and powerful motors. From sweeping brushes to trench excavation and stone dragging, these adaptable tools can rapidly cover a wide range of tasks.

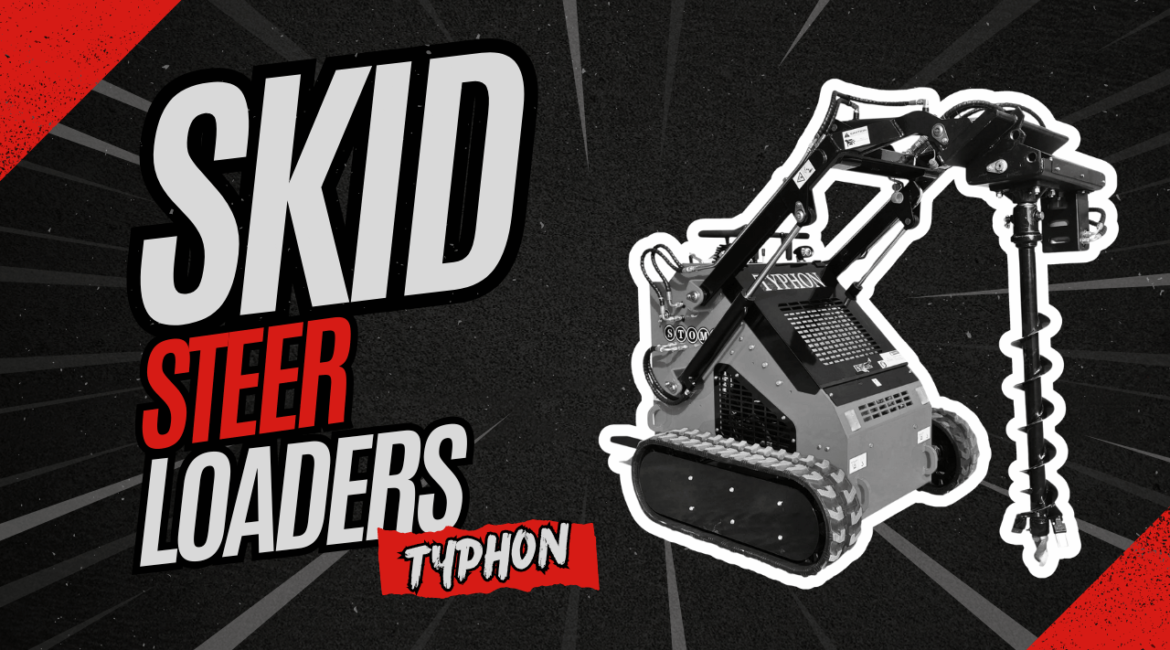

But you have to utilize the correct attachments if you want to optimize the powers of your skid steer and completely negotiate difficult terrain. Among the most often used and successful choices are the skid steer loader earth auger attachment.

Users of this special equipment may accurately and aggressively drill into various surfaces—hard-packed dirt or rocky terrain. Choosing and utilizing these accessories can help your skid steer run better and handle challenging tasks that would otherwise seem unachievable.

About ready to negotiate challenging terrain as an expert would? Everything from advanced drilling methods to preparing your skid steer for best performance to methods of operation improvement will be covered on this page. There is something here for everyone who wishes to courageously tackle difficult terrain, regardless of trade or equipment operating knowledge. Now let us start right away.

Skid Steer Loader Earth Augers: The Essential Drilling Solution

Aim And Adaptability

- Describes Their Nature: Designed to drill exactly cylindrical holes, skid steer loader earth augers include a rotating helical screw blade.

- Applications: Perfect for jobs including: utility pole placement, tree planting, and fence post installation

- Adaptability: Convert your skid steer loader into strong drilling equipment competent of traversing varied terrain and demanding circumstances.

Selecting Appropriate Earth Auger Attachment

- Why Size Matters: for daily chores, standard attachments are ideal.

- Designed for uneven terrain and rocky soil, heavy-duty alternatives

- Many augers can be customised to fit particular project needs by adding extensions for varying drilling depths.

- Flexibility: Change attachments to fit different terrain conditions, therefore guaranteeing effective performance for any work.

Ad Advantages of Earth augers in Challenging Terrain

Effortless Drilling:

- Easily cut through tough materials, much less physical effort than in conventional drilling.

- Particularly useful on uneven or rocky soils where conventional equipment often falls short.

- Mounted on skid steer loaders, earth augers provide speed, accuracy, and agility.

- Finish tasks quicker without sacrificing quality—even in the most demanding surroundings.

Dependable Performance:

- These attachments enable contractors and employees to approach demanding situations with comfort and confidence.

Your skid steer loader becomes a useful friend for building, landscaping, and agricultural chores armed with the correct earth auger attachment. Approach any terrain with dependability, speed, and accuracy, therefore simplifying and streamlining difficult tasks.

Why on Difficult Terrain Should One Use Skid Steer Loaders?

Skid steer loaders are especially helpful for negotiating the difficult terrain agricultural and construction workers often bring because of their amazing mobility. Skid steers can rotate and turn on a dime, unlike bigger machinery straining in confined regions or challenging terrain.

Drilling holes using earth augers is especially important for projects like fence construction or tree planting, as it will allow one to negotiate difficult terrain or extremely forested surrounds. This flexibility not only saves time but also improves operational safety by letting operators access far-off task areas free from concern of being caught.

Moreover, the effectiveness of skid steer loaders installed with earth auger attachments far exceeds conventional drilling techniques. Even though manual excavation might be time-consuming and labor-intensive, using skid steers transforms hours of backbreaking effort into rapid, under-control operation.

These machines can give continuous performance over several terrain types—from soft ground to hard-packed clay—by means of inventive hydraulic systems that power attachments smoothly, therefore acting as an unmatched replacement for individuals needing flexible equipment in demanding surroundings.

Their adaptability helps skid steer loaders shine on challenging terrain. Every project presents different difficulties from slope aspect to soil composition; thus, appropriate attachments are fairly important. For drilling through tougher foundation stones, for example, a bigger auger bit might be helpful; smaller bits simplify jobs in softer soils like sand or loam.

Operators help to minimize traditionally lost downtime during load changes using other equipment types by rapidly changing attachments according on real-time conditions and raising production.

Professionals in landscaping and construction would ultimately gain considerably from choosing a skid steer loader with flexible earth auger attachments.

Skid steers are a great tool for conquering difficult terrain as they combine great mobility, improved efficiency over traditional methods, and natural flexibility to many surface conditions. Using these conventional tools will surely speed up and improve the quality of your next drilling job.

Getting Your Skid Steer Ready for Perfect Use

Certain pre-operation tests and maintenance are highly crucial before starting your next drilling activity with a skid steer loader earth auger attachment. First look at the machine’s fluids: essential components whose ideal levels should be determined are engine oil, hydraulic fluid, and gasoline.

Check the filters as well; clogged filters could result in running engine failure or decreased performance. They should be, as they ought, neat and flowing. Not least of all take into account the condition of the tires; suitable inflation and tread depth help to keep traction on hard terrain, which is vital when driving in uneven or rocky surroundings.

Another crucial step in having your skid steer ready is matching the auger size to your project needs. Whether you are building fence posts or planting plants, Earth welcomes in a range of diameters and lengths intended for certain activities.

A smaller auger might be enough for intermediate soils, for example; however, it would suffer with hard-packed earth or rock formations. On the other hand, a huge auger could limit performance and tax your equipment. Early soil condition studies might direct your choice of attachment and prevent any potential problems later on.

Correct weight distribution and balance can help improve performance, particularly when utilizing a skid steer loader earth auger attachment. Apart from increasing agility, a well-balanced machine reduces too much stress on individual sections, therefore preventing likely early wear and tear. Make sure any extra weight or accessories follow manufacturer specifications. This meticulous attention to balance improves operational safety, which is a primary concern as incorrect weight distribution may cause mid-operation breakdowns or tipping occurrences.

Under demanding conditions, treating these early actions—performing extensive inspections, matching gear accurately, and obtaining appropriate weight distribution—with extreme care can significantly improve the performance of your skid steer. Starting with strong safety precautions from day one and using these performance standards will enable you to establish a strong basis for effective drilling activities directly tackling challenging terrain.

Methods of Operations for Enhanced Performance

Optimizing Skid Steer Loader Efficiency and Longevity on Uneven Terrain Precision in Operating Methodologies

Methodical Drilling Approach:

- Keeping a regulated drilling angle, approach hard substrates precisely.

- Various effective control methods help to decrease pointless effort and improve skid steer loader machine performance.

Tracking Drill Speed:

- Concentrate on the drill bit’s ground contact speed.

- Reduced pressure increases hydraulic system lifespan and output performance.

Velocity Management for Maximum Performance

Juggling Terrain and Speed:

- Steer wary of running big equipment on rough or unstable ground at high speed.

- Keep your speeds in line to avoid blade misalignment and too much wear.

Torque Management:

- To increase torque, somewhat speed up difficult operations.

- Smooth operations guaranteed by controlled speed guarantee durability not compromised.

Strategic Application of Hydroulic Attributes

- Changing hydraulic settings will allow you to adapt power delivery to material density.

- Press softer layers gently or use more effort for smaller stones.

Multi-tasking Efficiency:

- By allowing simultaneous lifting and drilling, hydraulic attachments help to save physical effort.

- These characteristics minimize hand involvement and increase output.

Using Information for Perfect Operations

- Interplay of Controls: o Know how hydraulic settings and speed control interact.

- Effective excavation brought forth by proper control saves time and money by streamlining processes.

Optimised Excavation:

- Using these methods guarantees skid steer loaders run at maximum capacity even under demanding circumstances.

- Contractors and operators gain from reasonably affordable, high-performance outcomes.

- Mastery of these best practices will help skid steer drivers improve their performance and safeguard their equipment, therefore guaranteeing long-term success in demanding surroundings.

Safety Notes About Earth Auger Attachments

Safety first even operating a skid steer loader with earth auger attachments. Using the right personal protective equipment (PPE) may assist to significantly lower the risks connected to heavy machinery operations. Operators should wear protective helmets; ear protection will aid against noise exposure; and steel-toed boots provide foot protection to avoid falling debris. High-visibility clothing also ensures your easy view on working areas where many workers might be close by. For the operator as well as for other employees, these procedures make the surroundings safer.

Following strict safety guidelines is very essential while running big machinery like skid steer loaders fitted with earth augers. Careful equipment inspection will assist to ensure that every component is in excellent working order prior to the start of operations. This covers checking safety guards are in place, fastener tightening, and hydraulic line leakage search. Throughout operation, keep awareness of your surroundings and correctly engage with ground crew members; hand signals or two-way radios help to minimize misunderstanding that can lead to mistakes.

More significant is establishing a plan for handling unanticipated issues developing during drilling operations. Terrain is not perfect; concealed utilities or rocks might cause major problems. Study site maps or use subterensive utility-seeking techniques to spot any bottlenecks before starting work.

Should you come into difficulty drilling—such as solid rock formations—stop right away and evaluate if it presents a hazard. Consider modifying your approach or contacting professionals before continuing instead of dragging the auger further into rocky terrain, which may damage your equipment or increase your chance of injury.

As per the skid steer loader earth auger attachments, following safety guidelines not only enhances operators’ individual safety but also promotes a caring culture among the complete project team. Following safety rules and regulations and being proactive about personal protective equipment helps one to ensure more effective working conditions and lowers the risk of unexpected incidents in tough terrain.

Expert Advice for Drilling Projects Aimed for Success

Navigating skid steer loaders during challenging drilling operations calls for both skill and preparation. Start with your drilling organization. Think about the necessities of your project, including locating water or electricity pipes buried below ground.

A well-designed skid steer system helps to minimize delays and boosts output. Marking drill sites reduces equipment wear by optimizing hole count. For example, a circular post-planting path could enable you to identify the ideal hole spacing and accelerate output.

Another vital tool is GPS technology.

Modern skid steers with GPS sensors might provide real-time position data relative to drill sites, hence improving accuracy. Different types of soil improve accuracy and aid in retaining depth during operations. GPS might help you offset elevation variations when erecting fence posts on uneven ground, therefore saving time and reducing guessing.

Strong troubleshooting abilities are even more crucial, as problems could develop during operation even with thorough planning. Auger operation is affected by hydraulic pressure loss; rocky or root-filled soils create equipment conflicts.

If an auger becomes caught when drilling into hard ground, don’t panic; it may be progressively reversed under continuous pressure forward to be removed without harming the machine or connection. Having a short reference book on skid steer mechanical problems and fixes can enable operators to spot minor problems before they become more severe.

Modern GPS systems, excellent design, and creative troubleshooting guarantee every drilling project runs well. Every component is essential to negotiate difficult terrain and provide operators with confidence they can overcome any barrier.

In Short, Breaking Through Skid Steer Loaders’ Promise

On many difficult terrains, skid steer loaders with earth auger attachments have been very helpful. Many experts have shared success tales about these machines running pretty successfully in challenging tasks, including drilling through rocky ground or uneven ground.

For building, gardening, and domestic chores, their adaptability makes them very helpful. Useful examples demonstrating its efficiency obviously show that anybody can navigate difficult terrain with the correct tools.

Still, regular maintenance is pretty vital to maximize your skid steer loader earth auger attachment. Careful cleaning plans and component wear and tear checks let you plan your maintenance carefully to prevent more significant problems down the road. Remember that choosing top attachments guarantees lifespan in any kind of work as well as improves performance.

Whether you like do-it-yourself jobs or are a seasoned professional, think about aggressively managing your hardest chores with skid steer loader earth augers. When operated in line with appropriate maintenance plans, they provide unparalleled efficiency and versatility. Accept this strong tool right now to improve your regular activities!