Skid Steer Snow Pusher vs. Blower: What’s the Best Attachment to Commercial Plowing?

Winter is a season of tests for commercial property managers and snow removal contractors. When time is short and the job seems daunting because of thousands of square feet of pavement, choosing the right equipment is what makes or breaks the project. However, the funny thing is, more than the weather, the most talked-about issue in commercial plowing is the tools: the brute-force Skid Steer Snow Pusher vs. the precision-engineered Skid Steer Snow Blower.

Without a decision on which tool should be used, the job will only be done less efficiently, which, in turn, will cost you time, profit, productivity, and even contracts. The noise around these two main attachments—the simplest one, the box, and the most complicated, the hydraulic—has been cut by this detailed guide, which helps you decide on the best way of commercial snow removal this winter. Knowing their pros and cons, you will not only be able to make your machine work more efficiently, but also you will be able to reduce wear and tear while providing the clean results your commercial clients are looking for.

The Unbeatable Efficiency of the Skid Steer Snow Pusher

The skid steer snow pusher connection is often referred to as the “box plow,” and rightly so. It’s a three-sided, containment-style tool made to shovel large volumes of snow and push them to a piled or discharged area. The development of the tool is based on one concept, which means that reliability and raw speed is directly derived from that, thus making it the most common method of clearing vast, open spaces such as big-box retail parking lots, industrial yards, or airport aprons. With this tool, one can approach a vast amount of snow in one go.

The pusher’s potency comes from the fact that it uses vertical side panels to enclose the snow thus, almost all the snow in front of the machine is taken, making the creation of “windrows,” i.e., the rows of snow left by traditional angled plows, minimal. The complex moving parts are missing from the pusher, therefore it requires minimal maintenance and has short downtime periods, which is very important in dirty, sub-zero temperature commercial snow situations.

Key Benefits of Using a Skid Steer Snow Pusher for Commercial Lots

The design of the pusher is aimed at volume and rapidity on a large, unobstructed surface. Its positive points make it a highly profitable tool for the majority of commercial applications.

1. Maximum Containment and Volume:

The important side walls trap the snow, allowing the operator to gather and transport huge amounts of material in a single pass, thus reducing the total number of times the parking lot needs to be crossed by half.

- Such containment features are imperative in instances when snow needs to be moved for a long distance, for example, clearing the middle of a large parking lot and pushing the snow for about 300 feet to the far edge.

- Pushers reduce snow spillage and messy cleanup by containing it, thus enabling the overall work to be finished faster on simple surfaces.

2. Superior Operational Speed and Fuel Economy:

As the pusher is a passive, mechanical attachment with no hydraulic motors or rotating parts, it requires minimal horsepower and flow from the skid steer’s engine.

- Operators can usually move at the highest speed that the conditions allow, thus leading to faster coverage rates and higher productivity (cutting edge “down-time” is maximized).

- The operation is less fuel-consuming due to its simplicity and lower hydraulic draw as compared to a snow blower’s continuous, high-demand operation.

3. Low Maintenance and High Durability:

The pusher is structurally sound and less vulnerable to a mechanical failure during a storm as it has very few (or no) moving parts (except trip edges on some models).

- Usually only the cutting edge (mostly rubber or steel) is the wear part, which is cheap and easy to replace in the field, thus, giving very little costly downtime.

- The lower-priced upfront investment compared to a blower makes the pusher a highly cost-effective entry point for contractors focused on basic high-volume clearing.

The Precision and Reach of the Skid Steer Snow Blower

What a snow pusher relocates, a Skid Steer Snow Blower gets rid of. For instance, the TYPHON Skid Steer Loader Snow Blower Attachment on your site, utilizes an auger and an impeller powered by a single source to take in and forcefully expel the snow via a rotating chute that can throw the snow pretty far. Such a powerful and precise tool comes handy, practically, in those few commercial plowing scenarios where space is limited and placement is very critical.

The blower attachment is the unquestioned champion when dealing with deep snow drifts or when snow must be placed over a pile, a fence, or into a specific, distant off-site location. It operates regardless of the snow depth, chewing through accumulations that would quickly leave a pusher spinning its wheels and losing traction. While slower than a pusher in covering open ground, the snow blower is superior in handling the absolute worst conditions and performing detailed, surgical snow removal.

When a Snow Blower is the Undisputed Champion?

The extraordinary characteristics of a snow blower enable it to tackle problems that a skid steer snow pusher cannot, thus, making it the most important site with specific environmental or space constraints.

Handling Extreme Snow Depth and Density:

Fundamentally the auger and impeller are made to forcefully break and process heavy, deep accumulations (usually 2 feet or more) and tightly packed snow that a skid steer can hardly push.

Even in deep drifts, the machine can keep going and maintain traction because the snow is continuously taken in and thrown, thus, the front of the machine is not overloaded.

It can slice through hard-packed snow and ice layers, thus, you get a cleaner road with less work than if you had to go over it again using a plow.

Unmatched Snow Stacking and Placement Control:

Through the hydraulic chute and the deflector, the operator can determine the exact direction of the snow stream thus, putting the material at the location where it is needed and nowhere else.

This is very important for commercial sites such as banks, apartment complexes, or retail centers where the parking spaces have to be saved and stacking needs to be done at a high level in order to make the most of the available space.

The blower can easily throw snow over the standard heights such as existing banks, fences, or retaining walls thereby overcoming the limited stacking height that a pusher experiences due to the closeness of the containment box to the machine’s frame.

Clearing Confined Spaces and Sensitive Areas:

Blowers can be used for the removal of snow from sidewalks, narrow drive-through lanes, and walkways between buildings, which are areas in front of loading docks where windrowing is not allowed.

By doing away with the necessity to “windrow” snow or deal with messy piles, they enable the production of an exceptionally clean finish without snow trails or leftover materials that require follow-up cleanup.

Since the snow is blown out and not pushed, the blower will not be the cause of potential harm to the sensitive ground features, curbs, or landscaping which, otherwise, may happen when a pusher scrapes aggressively.

Direct Comparison: Skid Steer Snow Pusher vs. Blower for Commercial Profitability

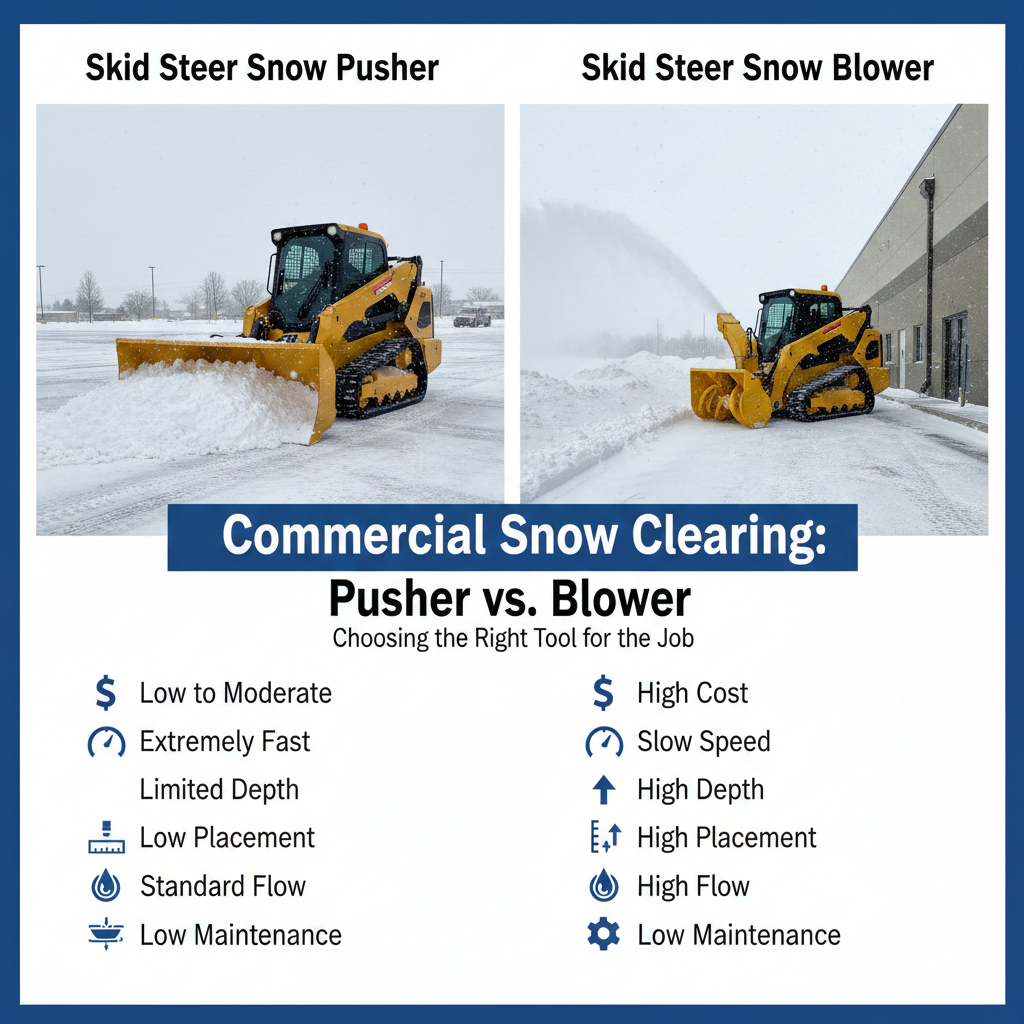

Usually, the choice between a pusher and a blower is a ground work one, which involves considering three factors – speed, cost, and terrain. Commercial profitability depends on speeding up the process while lowering labor and maintenance costs simultaneously. It is a quick, yet comprehensive, comparison of these two attachments with regard to the most important operational metrics presented in the following table which leads to the result.

| Feature | Skid Steer Snow Pusher | Skid Steer Snow Blower | Commercial Suitability |

| Initial Cost | Low to Moderate | High (Often 2-3x the cost of a pusher) | Pusher offers a quicker ROI. |

| Operating Speed | Extremely Fast (Machine speed) | Slow (Auger/impeller speed) | Pusher wins for quick coverage of large, open areas. |

| Max Snow Depth | Limited (Depends on skid steer weight/HP) | High (Handles deep drifts and heavy snow easily) | Blower is essential for heavy snow accumulation zones. |

| Snow Placement | Low (Straight push, creates one large stack) | High (Hydraulic chute allows precise casting) | Blower is required for sites with limited stacking space. |

| Hydraulic Requirement | Standard Flow | High Flow required for optimal performance | Blower requires a heavier-duty skid steer model. |

| Maintenance & Downtime | Low (Few moving parts) | High (Auger, impeller, motor, gearbox) | Pusher is more reliable during non-stop storm cycles. |

Operational Considerations: Speed, Maintenance, and Snow Stacking

The differences between these two machines become conspicuous when they are used for a long time. Usually, a single decision point—speed—is the most valuable asset in commercial plowing, yet it has to be balanced against the conditions.

Skid Steer Snow Pusher’s Speed Advantage is Contextual:

There is no doubt that the pusher is much faster in clearing a broad, open area of low to moderate snowfall (e.g., 4-8 inches of fresh powder). Such speed greatly cuts down on labor time and increases the efficiency of working large properties.

However, its speed advantage is lost in situations where one has to deal with deep snow or has to travel long distances backwards (up to 50% of the time) to return for the next push, which is called “up-time” inefficiency.

Since a skid steer snow pusher can only work in a straight line, there is an inherent limitation that forces you to frequently spend your time getting windrows or trails left when snow is spilled around obstacles cleaned.

Blower’s Maintenance Demands:

Such complex hydraulic systems are found in the TYPHON Snow Blower Attachment, among which are the auger, impeller, and motor, and hence, they need careful and regular maintenance.

Although full flow is not always absolutely efficient (it depends on the specific pump and motor), the maximum GPM your skid steer’s output should be is what allows you to achieve the maximum throwing distance and efficient operation.

The higher complexity implies that there is a higher possibility that a component failure during operation—an issue that is usually more costly and time-consuming to fix than just replacing a rubber cutting edge on a pusher—might happen.

The Cruciality of Snow Stacking:

In the thick of urban environments or tightly packed commercial properties, the ability to stack snow as high as possible is a main contract requirement. A pusher restricts stacking height because the attachment itself is near the machine, thus, it is difficult to lift the snow over a high bank.

A skid steer snow blower completely gets over this problem, giving the operator the freedom to throw the snow far beyond the already existing piles, fences, or retaining walls, thus, making the most of the limited storage space and keeping fire lanes clear.

In case the snow on a property needs to be taken away completely, the blower will be usually more effective in the loading of dump trucks as it can fill them quickly and neatly through the directed chute, thus, minimizing spillage as opposed to using a bucket or a pusher that has a limited lift capacity.

Making the Commercial Plowing Decision Skid Steer Snow Pusher vs. Blower

In the end, the best attachment is the one that meets the specific demands of the particular commercial property in the best way. Usually, a successful commercial plowing fleet needs both attachments to be able to work the different sites in their portfolio efficiently. The contractor who is wise does the property-layout-analysis before the first snowflake drops.

Matching the Attachment to Your Commercial Plowing Needs

Planning the property’s geometry, local snow patterns, and client’s budget serve as determinants for which attachment will yield the highest return on investment for the task.

For Large, Open, High-Volume Sites:

In case you are clearing a huge, square or rectangular open lot with a lot of perimeter space for snow storage (like a big-box store or warehouse yard), a skid steer snow pusher would be the clear winner, as it is fast and highly capable of holding the snow.

- The low maintenance and simplicity of the pusher guarantee that you can keep up with storm marathons without the risk of a hydraulic motor or an impeller breaking down.

- This option works best when the chief aim is that of maximum speed and fast turnaround time for business reopening.

For Restricted, Complex, or High-Drift Sites:

Should the property be laden with numerous obstacles, have tight corners, limited snow storage (like a multi-building apartment complex or a downtown bank parking lot), and/or be prone to deep drifting, then a snow blower would be absolutely necessary.

The reason for that being the great feature of the blower to precisely position the snow thus, stopping it from being piled up next to fire hydrants, loading dock doors, or designated handicapped parking spaces, hence, allowing for regulatory compliance.

Contractors located in areas such that regularly experience heavy, wet snowfall (over 10 inches per storm) will discover that the blower is the only attachment that can cope with the snow’s huge mass without the machine excessively struggling or losing traction.

Budget and Fleet Versatility:

Starting with a high-quality skid steer snow pusher is your most cost-effective solution, if you are restricted in budget, thus, you will be able to handle the majority of basic commercial plowing jobs straight away.

What is more, a pusher is the only viable option for contractors who mostly own mid-sized skid steers without high-flow hydraulics as a standard flow may greatly limit the performance and throwing distance of a blower.

The ideal, flexible fleet setup comprises of several skid steers fitted with pushers for fast, general clearing, and at least one high-flow machine fitted with a powerful snow blower for detailed work, stacking, and heavy drift removal.

Simply put, a skid steer snow pusher is like your high-speed freight train—it carries a huge load, but it can only move in a straight line and unload at the end of the track. On the other hand, a snow blower acts like your surgical tool —it’s slow, precise, and can do the impossible job of taking away the snow where there is no space left for putting it. By aligning the capabilities of each attachment with your specific commercial contracts, you not only achieve efficiency but also get a competitive advantage that lasts the whole season.

FAQs for Skid Steer Snow Pusher – Commercial Snow Removal

What is the primary difference between a skid steer snow pusher and a snow blower?

The fundamental difference between the two is the way they handle snow. Snow pusher is a containment box to move and pile large volumes of snow over a surface into a designated dump area. Snow blower attachment is a hydraulic-powered auger and impeller system to ingest, break up, and eject the snow via an adjustable chute, thus, allowing the snow to be casted at a considerable distance far from the cleared surface.

Which attachment is faster for clearing large commercial parking lots?

The Skid Steer Snow Pusher is generally faster for clearing large, open commercial parking lots, especially in light to moderate snowfalls. The operator can go at faster speeds since there are less moving parts hence, more area can be covered within a short period of time as compared to the slow and steady method of feeding snow into a blower.

Do I need a high-flow hydraulic system to run a skid steer snow blower?

There are a few smaller blowers that can work on standard flow, but to get the best performance, throwing distance, and work efficiency required for commercial use, a high-flow hydraulic system is highly recommended. The high-flow capability ensures that the motor driving the auger and impeller receives enough power (GPM) to break through and throw back heavy, wet, or deep snow forcefully.

Which attachment is better for clearing heavy, deep snow drifts?

The Skid Steer Snow Blower is the undisputed champion for clearing heavy, deep snow drifts (typically accumulations over 10 inches). Its design allows the auger to continually break down and evacuate the snow, thereby ensuring traction and movement are consistent, whereas a pusher will often lose traction or become overwhelmed by the sheer mass of the material.

What are the long-term maintenance differences between the two?

The snow pusher has significantly lower long-term maintenance costs. It is a simple, mechanical box attachment with wear parts mostly limited to the cutting edge. The snow blower, a complex hydraulic machine with such moving parts as the auger, impeller, chains, gearbox, and the hydraulic motor, has much higher long-term maintenance requirements and a greater risk of costly repairs.