The skid steer trencher attachment is a robust unit that has completely changed the way the apart of the in the different industries, such as construction, landscaping, utility, are, digging have been suspended, heim industries besides that.

This add-on turns a regular skid steer loader into a trenching machine that is very effective thus, operators can by little work they become able to dig narrow trenches with exactness and in little time.

Skid steer’s flexibility when it is combined with the trencher made it an absolute necessity not only for the contractors but for the landscapers too. Given the fact that it can easily go through narrow and tight spaces and do the same work which in other cases needs large machines, The skid steer trencher is a revolution in the area of earth moving machines.

The method of the skid steer trencher attachment mostly consists of a pulling rod equipped with sharp teeth that is capable of cutting through soil, rock, or any other material.

This rod is attached to a belt that can be positioned on the handlebar of the skid steer, so it is a simple piece of equipment to operate and handle.

The bolt is significant both in depth and width and thus, can be adjusted for different uses such as the installation of drainage systems or utility lines.

As cities expand their urban areas and the need to find efficient ways to dig grows, the skid steer trencher attachment is still the best solution for today’s trenching requirements.

Key Takeaways

- The different kinds of skid steer trencher attachments are versatile tools that can be used for digging trenches in different works such as landscaping, construction and agriculture.

- Along with the increased efficiency in labor works, the use of a skid steer trencher attachment can also lead to higher productivity on the job site which means the saving of time and labor costs.

- The various designs of the skid steer trencher attachments include chain trenchers, wheel trenchers, and micro trenchers. These are different kinds of products that each have a certain purpose of digging and they are differently designed.

- In case you decide to purchase a suitable skid steer trencher attachment, first of all, you need to ask proper questions regarding depth, width, and type of soil as well as to check the working condition of the site to make sure you delivered the right performance.

- The correct maintenance and care along with safety measures being followed, are the turning points for a long service life of skid steer trencher attachments and are necessary for safe operation as well.

Benefits of Using a Skid Steer Trencher Attachment

Efficiency is the main point of the benefits the users of a skid steer trencher attachment can enjoy. Usually, traditional trenching methods are labor-intensive or use large machines that can be hard to operate and time-consuming.

While at the same time, a skid steer trencher is able to achieve cutting of different depth and width with a very high speed, thereby, a very short time for the whole process is needed when compared to the manual work or other machines.

This efficiency directly results in monetary savings for the contractors as they would then be able to handle additional projects over a shorter period of time without lowering the quality of their work.

Alongside precision, which is the other advantage of a skid steer trencher, It is very easy for the workers to fulfill even the most specific requirements of the projects because of the possibility of setting the trench depth and width exactly as necessary.

Practically, if we mention irrigation systems and the electric conduit as two installations where the precise measurements are very significant, we will make it even clearer why such precision is absolutely necessary.

The thin trench left by the attachment also helps to reduce disturbance of the soil which in turn is good for the landscaping industry where the preservation of existing vegetation becomes the main concern.

Types of Skid Steer Trencher Attachments

Skid steer trenchers differ in their designs, each of which describes the various specifications that the device is able to tackle.

The chain trencher is a popular and typical example of a skid steer trencher type, whereby a continuous chain with teeth that bore into the ground as it revolved was being used. Such a type is just right for ordinary trenching tasks, as well as dealing with different sorts of soils running from soft loam to even harder clays.

Besides that, the chain trenchers not only could be used in different works and so on, but also they were depth adjustable, which made them proper both for shallow and deep excavations.

The other one is the wheel trencher by which a turning wheel with razor-sharp edges cuts through the earth. Comparatively, a wheel trenchers’ pace is always higher than that of the chain ones and are especially good at achievement of this enough in soft soils.

If the ground is rocky or tough, they are less useful, but they are very good at applications when speed is the key factor. Besides that, there are always some special trenchers for the certain tasks, for instance, rock trenchers, which are reinforced with the strongest forged teeth for the hardest geological structures and also vibratory trenchers that just use the vibration to break the hard soil before digging.

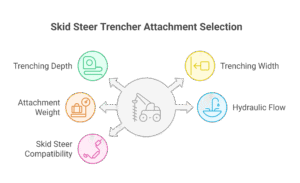

Choosing a proper skid steer trencher attachment will lead to a better performance and a more efficient work. There are numerous issues operators need to evaluate, among which the soil type is of prime importance.

For example, a chain trencher with toughened teeth is probably the best choice if the project background is in rocky terrain or compacted earth. On the other hand, if sand or soft soil dominate the site, then a wheel trencher can become the first choice by virtue of its swiftness and productivity.

Another factor is the dimensions of the trench that are needed and this is a really important aspect. Different widths and depths of cut are the features that different attachments offer, so, taking the one that is the closest to your project’s specifications is the most correct way.

To clarify, by the question what would be the most appropriate tool for achieving very accurate cuts necessary when working with utility lines, it is conceivable to say that the one designed for precision cutting will be the best choice.

Moreover, the information about the compatibility of the attachment with their very own skid will take up the place of the operators as they will have to assure it can accept the power and weight of their machine without affecting the performance.

Tips for Using a Skid Steer Trencher Attachment

A skid steer trencher attachment will be more effective if operators follow the numerous best practices that they have to observe during use. Firstly, it is very important to know the controls and how it operates both the skid steer and the trencher attachment before starting any project.

Besides just knowing, one will become efficient in operation and will also be able to get better results by adjusting the settings for depth and width. In this case, a pre-operation inspection both of the skid steer and the attachment can be helpful in uncovering the ‘invisible’ issues that might lower the performance of the machine.

He’s right to say that when you first embark on a trenching job, it would be better to get a feel for the machine and its handling characteristics at a slow speed.

As confidence builds, you should gradually increase the speed, reaping in benefits such as better control of trench depth and width as well as smoother operation.

Besides this, the operators should always be on alert, particularly in the case of urban work areas or when close to other utilities. Utility lines that are underground could be affected by the work if these are not correctly marked out beforehand, so ensure safety during the whole process by carrying out this easy task.

Maintenance and Care for Skid Steer Trencher Attachments

Regular Inspections

One should always do regular inspections to check if the chain or the wheel teeth have worn out, and if the frame or the hydraulic parts show-any signs of damage.

Not only that maintaining these parts in good condition will improve the performance though it will also lessen the risk of breakdowns during the operations.

Lubrication and Greasing

Lubrication is a part of the maintenance process that should not be neglected. Most of the trencher attachments have moving parts and in order to these parts not to be damaged by friction, they need to be greased on a regular basis.

Operators should check the manufacturer’s instructions for a specific type of lubrication, the frequency, and the kind of grease that is recommended for their particular model.

Cleaning and Debris Removal

Furthermore, when cleaning the attachment after use, the removal of the dirt and debris that may have collected during the operation of the equipment is possible and thus the lifespan of the equipment is extended.

Safety Precautions When Using Skid Steer Trencher Attachments

The safety factor must never be underestimated even during the easiest tasks with the heavy machines. The best thing any operator, who is dealing with the use of the skid steer trencher, can do for himself is to wear Personal Protective Equipment (PPE) like a hard-hat, safety goggles, gloves, and safety boots as this will protect him from the most common injuries that occur during the operators’ work.

Besides this, it is crucial that no one is found within the danger zone of the work area while the machine is working and this is only achieved by informing all the members of the team beforehand.

Prior to engaging the use of a skid steer trencher attachment, operators should take a walk around the site to do a full hazard identification which may include potential hazards like underground utilities or soft/unstable ground conditions.

Utility locators are very helpful devices that should be looked into, as they are efficient in avoiding accidents resulted from hitting by mistake buried lines while digging.

Likewise, the open telefcommunication between the personnel could help a lot in ensuring safety. This is because every person will be in a position to get instantly updated about the situation on ground and any alteration made in the plan.

Conclusion and Final Thoughts

The skid steer trencher attachment is basically the next level technology in digging and has the capability to work efficiently and accurately to a wide range of trenching tasks.

Learning about its advantages, different styles, factors to choose the right one, tips to use, care, and safety can allow them to be more effective whilst they face less dangers which are inherently present when doing trenching work.

Over time, the construction and landscaping sector will always be in need of this piece of equipment as they continue to become more industrialized and require a more convenient way to move soil.