Mix and Pour On-Site: Should You Get a Skid Steer Concrete Mixer Bucket?

Construction and landscaping businesses operate in a very competitive environment where one of the key components of profitability is efficient work. Time spent waiting for materials or managing manual labor is understood by every contractor and credited to money lost from the budget. This can be easily solved by Typhon Stomp skid steer concrete mixer bucket.

As such, the question that becomes important to both fleet owners and independent operators is whether investing in a skid steer concrete mixer bucket makes financial sense. In fact, for owners of multifunctional machines like the TYPHON STOMP Mini Skid Steer, the possibility of enhancing the equipment through attachments is a huge plus.

The concrete mixer bucket not only converts your standard loader into a mobile batching plant, but it also holds the promise of making your operations more efficient and less costly. The question, however, is whether the advantages proposed by the product are real.

This piece of writing is a thorough analysis of the features, costs, and expected benefits of purchasing this great attachment. Furthermore, it is shown how mixing and pouring on-site can be a game-changer in your work, help in decreasing your reliance on third-party suppliers, and eventually increase your profitability.

Whether your work is fence post setting in a remote area or patio installation in a backyard, your business growth and success depend on understanding the cost-effectiveness of this tool.

What is a Skid Steer Concrete Mixer Bucket?

The skid steer concrete mixer bucket is a specially designed hydraulic attachment that can load, mix, carry and dump concrete. It is very different from the stationary traditional mixer that requires manual wheelbarrow to transport concrete from the mixer to the site.

First, it leverages the mobility of your skid loader to take the mix where it is needed. This attachment normally has auger(s) or paddle(s) for mixing concrete that are powered by skid steer auxiliary hydraulic system and hence makes a uniform mixture of cement, sand, and aggregate.

- Hydraulic Power: The mixer taps into the skid steer’s hydraulic system and harness the power of the machine to rotate the internal augers. Consequently, there’s no need for an external gas engine or electric power source, thus reducing mechanical complexity.

- Self-Loading Capability: Some of the newest buckets can be used to scoop up loose aggregates from a pile just like a regular bucket. This “self-loading” functionality greatly decreases the physical work of shoveling the materials into the drum.

- Precision Discharge: These mixer buckets usually have a side or bottom discharge chute, and occasionally a flexible hose is included. This makes it easy and neat to pour concrete into post holes, molds, or trenches without spilling and wasting as when indiscriminately dumping from a regular bucket.

The “Worth It” Factor: ROI and Efficiency

The most important factor when deciding whether the purchase of a skid steer concrete mixer bucket is a wise decision is ROI (Return on Investment). Short loads of ready-mix concrete for smaller projects can be very expensive due to ‘under-load’ charges and wait times.

With a mixer bucket, you are back in control and can make only the quantity you need, at the time you want it. In many cases, the initial outlay for the attachment is returned through savings on ready-mix delivery and less labor.

- Elimination of Waiting Time: Downtime is the biggest hidden expense in construction. By having an on-site mixer, you won’t be dependent on the schedule of the concrete truck anymore. When the site is ready, you can start mixing and thus keep your crew continuously engaged.

- Reduced Manual Labor: Carrying wet concrete in a wheelbarrow can be very exhausting, frequently resulting in delays due to worker fatigue. A mixer bucket is great for carrying the heavy load, so your crew can concentrate on finishing and leveling rather than physically carrying the mix.

- Access to Remote Sites: Ready mix cement trucks are normally large and cannot enter tight backyards, soft terrains, or remote fence lines. On the other hand, a small skid steer like the TYPHON STOMP fitted with a mixer bucket is capable of getting through such sites, thus the pour site is easily reached.

Versatility: More Than Just Mixing Concrete

Often times, a skid steer concrete mixer bucket turns out to be a very versatile tool apart from the one suggested by its name. It is not restricted to only wet concrete; you can even consider it as one of the crucial tools for handling various other materials.

Because of this increased utilization, the attachment could be a more financially viable solution in your fleet. Assume that you are currently utilizing a TYPHON Skid Steer Loader Trencher Attachment or a Land Leveler, then by simply adding a mixer bucket, your landscaping or utility work will be full-service and efficient.

- Dry Material Mixing: Skid steer concrete mixer buckets can do much more than mix wet concrete. You can utilize them for mixing dry mortar, stucco, or even animal feed. Thus, these buckets offer support in both construction and agriculture.

- Sandbag Filling: Using the discharge chute, one can very easily and efficiently fill sandbags for flooding or any type of construction barriers. What used to take a number of people and be a multi-step task can now be done by one person.

- Grout and Epoxies: If the application is flooring or industrial, then the self-leveling grouts and epoxies that require thorough mixing and immediate pouring to prevent early setting can nicely be handled with the mixer bucket.

Comparing On-Site Mixing vs. Ready-Mix Delivery

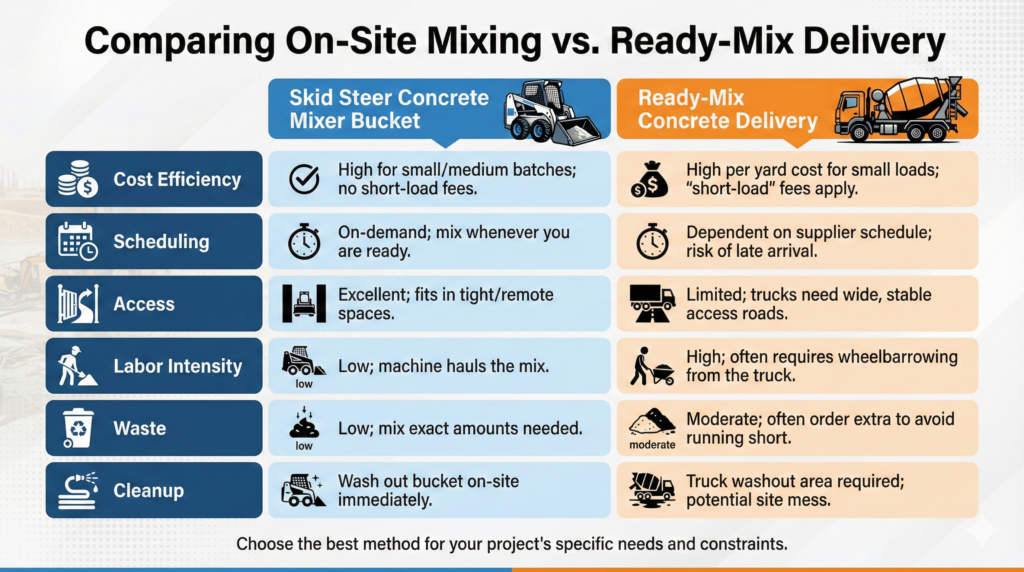

A side-by-side comparison will make the advantages and disadvantages more obvious. The table below summarizes the main differences between the use of a skid steer concrete mixer bucket and the traditional ready-mix concrete delivery services for small and medium projects.

| Feature | Skid Steer Concrete Mixer Bucket | Ready-Mix Concrete Delivery |

| Cost Efficiency | High for small/medium batches; no short-load fees. | High per yard cost for small loads; “short-load” fees apply. |

| Scheduling | On-demand; mix whenever you are ready. | Dependent on supplier schedule; risk of late arrival. |

| Access | Excellent; fits in tight/remote spaces. | Limited; trucks need wide, stable access roads. |

| Labor Intensity | Low; machine hauls the mix. | High; often requires wheelbarrowing from the truck. |

| Waste | Low; mix exact amounts needed. | Moderate; often order extra to avoid running short. |

| Cleanup | Wash out bucket on-site immediately. | Truck washout area required; potential site mess. |

Key Features to Look For When Buying: Concrete Mixer Bucket

Not all concrete mixer buckets available in the market give you the same value for your investment. Thus, when selecting one for a high output machine such as the TYPHON STOMP, you must be sure that the features of the product are those that support its strength, durability, and fuss-free operation. The style of the spiral and the structural strength of the mixing chamber go hand in hand in determining the unit life.

- Hardox Steel Construction: Ensure that you get a bucket that is manufactured in high-wear resistant steel also known as Hardox. Concrete contains very hard particles, and if a steel bucket is used without special treatment, it will be worn out very fast. You can tell that the bucket is top quality if it has reinforced paddles and drum walls that can hold up even if the grinding action continues for years.

- Two-Way Rotation: You expect a reputable, efficient concrete mixer to be able to work in both directions. Mixing is the task that is done when the auger rotates in one direction. When the direction is reversed, it is often to push the material into the discharge chute. In addition, if the mix becomes too stiff, it is very easy to unclog the machine.

- Protective Grating: You need a solid upper grate for your safety as well as for the workers around you who may be at risk. The grate not only prevents unwanted contact with the moving auger, but it also gives you some freedom to break the bags by simply dropping them on the grate. This is very helpful for speeding up the loading process.

Maintenance and Care for Long-Term Use

Proper maintenance of the skid steer concrete mixer bucket is the only way to extend its useful life. Concrete can quickly harden inside the machine if it is not cleaned immediately after use, turning the unit into a nightmare. If you are disciplined with your cleaning routine, your attachment will always be in excellent working order and you will not have to replace your unit as often.

- Immediate Washout: The bucket must be emptied of any concrete and the inside should be washed with water right after use, no matter what. A washout cycle should be performed with water and gravel after a scraping brush has removed the accumulated residue from the drum and paddles. Any remaining residue will continue to harden if not removed.

- Greasing Moving Parts: You should always keep the bearings and seals for the hydraulic motor and auger shaft well lubricated. The lubricating effect produces a barrier that prevents the entry of water and dust. If these contaminants get into the components, it causes wear and early failure. Besides, you should not be allowed to install the hydraulic coupling as dirty, so it needs to be cleaned before hooking up to the Skid Steer Loader.

- Hydraulic Hose Inspection: Routinely check for signs of deterioration or leaks and then replace them if found. Remember, any decrease in pressure will lead to a fall in mixing performance when you depend on the skid steer hydraulic flow for the bucket.

Final Call to Make: Skid Steer Concrete Mixer Bucket

To sum it up, contractors who often do small to medium concrete projects can not go wrong with a skid steer concrete mixer bucket. They get an amazing level of efficiency and autonomy that they would have never imagined possible with the traditional way of doing the concrete batch. By making their skid steer loaders into an independent mixing plant, they free themselves from the hassle of dealing with ready-mix trucks and the labor pains of manual work.

TYPHON STOMP Mini Skid Steer owners, will find this attachment to be a very useful companion in their line of accessories which already includes the Fork Pallet Attachment, Earth Auger, and Trencher.

By adding this exquisite tool to your arsenal, you position your business to be capable of completing a wider range of jobs with only a small increase in overhead. Giving this investment the credit it deserves by way of time savings, labor reduction, and the ability for you to take on more complex projects with a limited access will be a good strategy moving forward!

FAQs: Skid Steer Concrete Mixer Bucket

What is a skid steer concrete mixer attachment?

Basically, a skid steer concrete mixer attachment is a piece of hydraulic equipment that gets mounted on a skid steer loader. It harnesses the hydraulic power of the machine to rotate the internal paddles/auger that are in the mixing drum. Hence, the operator is able to mix cement, sand, and water at the spot and then transport it straight to the pour site.

How does a skid steer concrete mixer work?

It operates by hooking up to the skid steer’s auxiliary hydraulics. Thus, the operator stays in control by simply switching the internal auger rotation directly from the cab. Original ingredients are scooped from the top grate, mixed and then the operator drives to the spot and unloads the concrete by reversing the auger or by opening a chute.

Is a skid steer concrete mixer bucket worth the money?

Absolutely, it is a very cost-saving option for the majority of contractors. It only gets rid of short-load fees, from concrete trucks mostly, that traditional mixers incur, gives you lesser labor to do for wheel barrowing and minimizes downtime, while waiting for deliveries. It also enables you to perfectly schedule and use the materials.

What is the mix ratio for a skid steer concrete mixer?

Although the attachment is capable of mixing any customized ratio, a conventional concrete mix ratio is generally 1 part cement, 2 parts sand, and 3 parts aggregate (stone). Water is added little by little until the right consistency is attained. Make sure that you follow the cement manufacturer’s instructions when it comes to structural requirements.

Can I use a concrete mixer bucket for other materials?

Of course, yes! The great thing about these skid steer concrete buckets is that they can mix mortar, stucco, grout, animal feed, and fertilizer as well as transporting sand, gravel, and soil. Moreover, they can be used for filling sandbags by means of the discharge chute.

How do I clean a skid steer concrete mixer?

Cleaning should be done hastily after the job is done. Get the mixer filled with water and a couple of shovels of gravel, turn the motor on and run it for a few minutes. The gravel serves as an abrasive that scrubs the drum walls. Let out the dirty water and then the exterior and chute should be sprayed down with a high-pressure hose.

What size skid steer do I need for a mixer bucket?

You will be required to have a larger skid steer if the capacity of the mixer bucket is bigger. As an example, mini skid steers like the TYPHON STOMP can handle smaller buckets (e.g., 100-200 liters). However, if you are dealing with larger buckets (e.g., 500+ liters), then you will need full-size skid steers having higher operating capacities and hydraulic flow rates. It is very important to always ensure that the weight specifications of the attachment correspond to the tipping load of your machine.