Extending Your Attachment Lifespan: The Ultimate Skid Steer Attachment Maintenance Guide

Having a skid steer jumps your business to a different level, be it construction, landscaping, or farming, but more than the machine, the seasoned operators know it is the tool attached that really counts. Whether you are operating a small TYPHON STOMP Mini Skid Steer or a heavy-duty loader, your work’s efficiency is dependent on the state of your equipment Skid Steer Attachment Maintenance.

If you ignore your tools, it is almost inevitable that you will be facing unexpected machine breakdowns, your projects will get delayed, and hazards will escalate. Hence, having a strict maintenance routine for your skid steer attachments can be considered your tool kit’s most valuable asset. By giving buckets, trenchers, and augers special attention, you will not only keep them at top performance, but also strongly extend their service life.

By following a complete skid steer attachment maintenance schedule, you will be separating yourself from a loss-making project and attracting profitable projects. For one, hydraulic attachments are high-tech pieces of engineering which go beyond a simple washing post-usage.

They call for a forward-looking strategy that foresees wearing out even before it brings about a breakdown. The intention of this manual is to be your faithful companion in the journey of maintaining your equipment in new condition. We are going to thoroughly explain the correct care in mechanics thereby exploring everything right from hydraulic hygiene to structural inspections.

When you are armed with the right skid steer attachment maintenance knowledge, your SkidSteerLoader.online tools such as Skid Steer Loader Earth Auger Attachment and 4-in-1 Bucket will be your reliable companions for years.

Base of Trust: Pre-Shift Visual Checkups

The best form of skid steer attachment maintenance comes even before starting the engine. It is a pre-shift visual check that has to be a non-negotiable habit if you want to be safe and productive at work. This quick glance every morning helps you spot small technical glitches that can turn into dangerous failures if not remedied in time.

- Pick apart Structural Integrity: take a slow paced lap around your attachment while you visually examine stress cracks, broken welds, bent frames, etc. don’t forget the quick-attach plate area as this is the place where stress is concentrated.

- Focus on Hydraulic Components: Check all hoses thoroughly to see if there are any signs of abrasion, bubbling, cracks or leaking, and whether the flat- faced couplers are not broken for even the smallest nick has the potential to introduce dirt.

- Ensure Fastener Security: A skid steer’s vibration is so intense; using a wrench, you can spot-check that nuts, bolts, and pins have not gotten loose, otherwise, any of these parts might get detached during operation.

Lubrication: The Most Crucial Skid Steer Attachment Maintenance Task

Grease is what keeps a machine’s joints moving freely if the hydraulic system is its muscle. Without it, friction between metal parts would and is the most significant part of skid steer attachment maintenance in a discussion on choices of essential.

The absence of it causes metals to produce heat very fast and metal shavings, which in turn scratches the joints. This phenomenon leads to a loosening of joints thus making the attachment unsteady which involves both safety risks and damage risks to the attachment itself that will consequently damage other components.

- Identify All Zerk Fittings: As noted above, different tools vary in their needs; a Skid Steer Loader Grapple has many more moving parts than a pallet fork, so check the manual to make sure no grease point is forgotten.

- Pick Grease of the Highest Quality: It is crucial that no compromises are made when it comes to grease quality; therefore, a heavy-duty lithium complex grease or molybdenum-disulfide grease should be used. These greases are capable of handling extreme pressure and shock loads, which are typical during skid steer usage.

- Cleaning Before Greasing: This applies especially to zerk before a grease gun is attached, always wipe it clean, so as not to force any sharp particles such as sand and grit inside, which will turn your grease into a grinding compound.

Hydraulic System Hygiene and Fluid Management

Your attachments are powered by the skid steer’s hydraulic system, making fluid cleanliness a top priority in effective skid steer attachment maintenance. Contaminated oil is the number one killer of hydraulic pumps and motors.

Keeping the system sealed and clean ensures that your high-performance trenchers and augers deliver maximum torque without overheating or stalling.

- Inspect Couplers Relentlessly: Before every connection, wipe the couplers on both the machine and the attachment with a clean rag; a single grain of sand can damage sensitive hydraulic valves.

- Monitor Fluid Levels and Quality: regularly check the hydraulic fluid level and look for signs of cloudiness or a burnt smell, which indicate contamination or overheating that requires immediate attention.

- Adhere to Filter Schedules: change your hydraulic filters strictly according to the manufacturer’s recommendations, as a clogged filter restricts flow, reduces power, and puts immense strain on the system.

Managing Wear Parts: The Sacrificial Components

All ground-engaging tools have their wear parts half the battle of skid steer attachment maintenance is knowing when those parts have to be changed. The main effect of using tools with worn-out teeth and areas is the reduction of efficiency, increased fuel consumption, and machine frame and hydraulic parts will undergo more stress and eventually get damaged.

- Turn-over and replace Bucket Teeth: Keep your bucket in good shape by changing its teeth when they are dull. Doing this will help maintain the digging efficiency and prevent wear on the bucket lip.

- Inspect Auger Pilots and Flights: Bit of pilot and teeth are crucial in Skid Steer Loader Earth Auger Attachment; if they are ineffective your hydraulic motor will be forced to work harder and the auger will not penetrate the ground.

- Maintain Trencher Chain Tension: Loose chain on a trencher produces the slapping that damages the boom while over-tight chain causes bearing wear; therefore, chain tension must be regularly adjusted including it in your skid steer attachment maintenance checklist.

Art of Cleaning and Storage

The way you store your tools is equally necessary to how you use them. Not taking care of your tool during the off-season or even just overnight can easily erase all your efforts. Thorough cleaning combined with proper storage count among the major pillars in skid steer attachment maintenance that help to ward off rust, corrosion, and wear of seals.

- Rinse Off After Work: Corrosive substances such as fertilizer, salt or acidic soil on your equipment are a big no as they can cause rust and paint coming off. Remove them immediately using a pressure washer.

- Shield Hydraulic Connections: It is a good idea to either connect the male and female couplers together (if possible) or use dust caps to keep the hydraulic system sealed from air and moisture during storage.

- Keep In a Covered Place: UV rays can crack hydraulic hoses and rain causes rust; therefore always keep your attachments indoors or if that isn’t possible, cover them with a heavy-duty waterproof tarp in case of outside storage.

Step Up Your Game: Troubleshooting

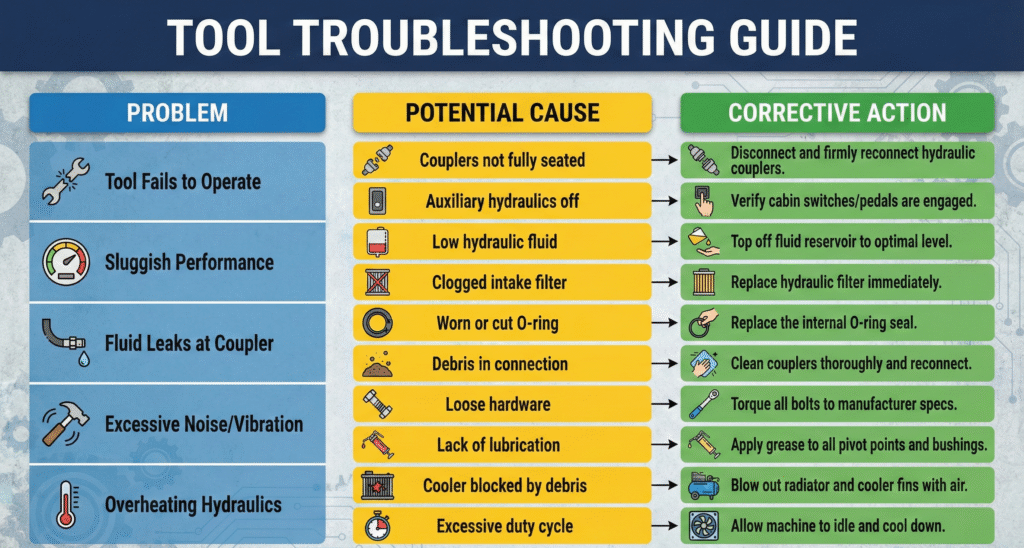

Even with the most rigorous skid steer attachment maintenance plan, problems can arise. Being able to diagnose issues quickly not only saves a lot of time but also reduces the incurred costs. You are invited to use the chart below for identifying and fixing the common issues.

Table: Skid Steer Attachment Maintenance Troubleshooting

| Problem | Potential Cause | Corrective Action |

| Tool Fails to Operate | Couplers not fully seated | Disconnect and firmly reconnect hydraulic couplers. |

| Auxiliary hydraulics off | Verify cabin switches/pedals are engaged. | |

| Sluggish Performance | Low hydraulic fluid | Top off fluid reservoir to optimal level. |

| Clogged intake filter | Replace hydraulic filter immediately. | |

| Fluid Leaks at Coupler | Worn or cut O-ring | Replace the internal O-ring seal. |

| Debris in connection | Clean couplers thoroughly and reconnect. | |

| Excessive Noise/Vibration | Loose hardware | Torque all bolts to manufacturer specs. |

| Lack of lubrication | Apply grease to all pivot points and bushings. | |

| Overheating Hydraulics | Cooler blocked by debris | Blow out radiator and cooler fins with air. |

| Excessive duty cycle | Allow machine to idle and cool down. |

The Reasons Why Documentation Should be Part of your Maintenance Routine

One area of skid steer attachment maintenance that is often disregarded is documentation. Maintaining a record of all inspection, repair, and replacement activities equips you with a good understanding of the state of your fleet.

Besides, it makes maintenance schedule much easier and should you need to resell your equipment, it will considerably justify the high price tag.

- Set Up a Maintenance Log: Get a simple notebook or digital file for each attachment and keep track of greasing, oil changes, and part replacements by date.

- Note Hour Usage: If your skid steer is hour meter equipped, record when you did specific maintenance work so that you will be able to predict your next service interval with better accuracy.

- Plan Review Sessions: Go over your records quarterly and ascertain whether it is one particular attachment that always breaks down. This might help you identify if it is operator error or the subscription of a replacement part is overdue.

FAQs – Skid Steer Attachment Maintenance

Why is skid steer attachment maintenance so important for resale value?

Efficient Skid steer attachment maintenance results in a well-kept tool that is ready for resale and with a documented history of care that proves to potential buyers that the tool has not been abused. Buyers generally pay more for nice tools with tight bushings, original paint condition, no hydraulic leaks, etc., than for the ones which have been neglected.

How does proper maintenance improve job site safety?

Regular maintenance of skid steer attachments reduces the chances of mechanical failures that potentially cause injuries. For instance, if a bucket pin comes loose, a loosed load may fall suddenly while a bursting hydraulic hose may spray hot oil at a bystander. The daily use of your gear will be safe for you and everyone around you if you maintain and inspect it properly at all times.

What happens if I skip greasing my attachments?

Skipping the lubrication step in your skid steer attachment maintenance routine leads to rapid wear of pivot pins and bushings. Without grease, friction generates intense heat and metal shavings, which grind away the joint. This results in “slop” or play in the attachment, making it difficult to control effectively and eventually leading to structural failure.

How do I choose the right replacement parts for maintenance?

It is always advisable to use OEM (Original Equipment Manufacturer) parts or premium aftermarket parts with the right durability standards for your skid steer attachment maintenance when replacing parts. Cheap and lower quality parts tend to have a poor fit and wear out quickly, leading to frequent replacements and may also cause damage to other components.

Is winter maintenance different from summer maintenance?

Yes, seasonal changes affect skid steer attachment maintenance. During winters, it is important to know that the hydraulic fluid you are using is for low temperatures so that cavitation does not occur. Whereas in summer, it is more important to ensure cleanliness of the cooling system so as not to overheat your machine. Regardless of the season, keeping your attachments clean and lubricated should always be your top priorities.

How often should hydraulic hoses be replaced?

One of skid steer attachment maintenance tips is that when hydraulic hoses begin to show signs of cracking, blistering or serious abrasions that expose steel braiding, they should be replaced immediately. While some professionals recommend proactive replacement every 2-4 years based on UV exposure and usage intensity to avoid sudden bursts at the job. Even though these hoses may look okay on the outside, it is still a good idea to do a thorough check for hidden damages.

Follow A Strict Skid Steer Attachment Maintenance

From the experience point of view, mastering skid steer attachment maintenance is a full investment with many returns in terms of pick, safety and profit. In doing so, you will be changing your equipment that is always in the red to a reliable asset.

Following the checklist of this thoroughly—inspecting daily, greasing regularly, managing fluids, and storing properly—to ensure that your TYPHON STOMP Mini Skid Steer and its attachments are always ready for the next challenge.

Do not let neglect eat into your bottom line. embrace a culture of care and watch your equipment lifespan extend significantly. For high-quality, durable attachments that are worth maintaining, visit SkidSteerLoader.online and equip your fleet with the best tools in the industry.