Introduction: What Is a Skid Steer Loader?

A skid steer loader ranks among the most versatile and robust pieces of equipment, which are commonly found in the construction, landscaping, agriculture, and industrial sectors.

Despite being modest in size, the machine is incredibly powerful and, thus, it is the one that is usually chosen when heavy lifting, grading, digging, or hauling are to be done in a quick and efficient manner, especially if the place is a tight-spaced one.

Moreover, due to the “skid-steering” mechanism, the loader can turn in the space of its own footprint, and as a result, it is far more agile and can be controlled more precisely than many larger machines.

Essentially, it is the Swiss Army knife of the construction industry. If the user is a contractor digging the ground for a new building, a farmer feeding animals, or a landscaper moving the soil, a skid steer loader is the one that will willingly and easily adjust to the requirements of the user.

Thanks to a wide range of attachments, this machine can be changed from a loader to a trencher, snowplow, forklift, or even a sweeper in only a few minutes.

The capability of the skid steer loaders to produce such a big effect with such a small input is the thing that differentiates these machines not only by their compact design.

These machines are highly dependable and need minimal maintenance; besides, they can lift a substantial amount of weight in relation to their size. Knowing their working principle and the factors that make them so indispensable is the key to unlocking their full potential, be it for business or personal projects.

History and Evolution of Skid Steer Loaders

The history of skid steer loaders resembles an exciting trip which started in the late 1950s. The saga is initiated by Cyril and Louis Keller, the two brothers from Minnesota, USA, who received a request from a turkey farmer to invent a small, agile machine that would be capable of cleaning the barns.

Compact and three-wheeled, the brothers’ loader, which could turn within its own length, was the machine that marked the very beginning of the first skid steer concept.

The Melroe Manufacturing Company (now Bobcat Company) got interested in the invention and after it refined the design and released the M-400, the very first four-wheel skid steer loader. This inventive breakthrough not only changed the whole compact equipment industry but also let the “Bobcat” brand become a worldwide synonym of skid steers.

The design changed quite a lot over the years. The first ones were simple mechanical machines, whereas today’s skid steers are equipped with complex hydraulics, electronic controls, and comfortable cabs. The transition from the evolution also led to the development of tracked versions that are more stable and have better traction on the uneven or muddy surface.

Skid steer loaders have gone beyond being mere instruments; they are technologically-driven heavy hitters at present. The producers are not stopping their efforts but striving towards electric skid steers, driverless models, and AI-assisted control systems that enable the most accurate operations.

What was once just a simple loader has profoundly changed into a multi-functional platform which is, by and large, the embodiment of the innovation and the efficiency of the modern equipment design.

How Does a Skid Steer Loader Work?

Essentially, a skid steer loader is combined of and operated on a straightforward but highly efficient idea: different wheel speeds. Wheels (or tracks) on each side of the machine are the independent drivers. By making one side faster than another, the loader “skids” to turn – this is where the name comes from. In fact, this allows it to turn within its own radius hence the amazing maneuverability in very small, confined spaces is achieved.

The Mechanics Behind Its Power

A robust diesel engine hooked to a hydraulic setup, which is responsible for not only the movement but also the attachments of the loader, lies just under the metal hood.

The lifting arms, tilt devices, and any other tools like augers or grapples can get the pressurized liquid to operate from the hydraulic pumps. This union of a rather small layout with hydraulic efficiency makes the machine to be a powerhouse and still agile at the same time.

Hydraulic System and Controls Explained

Methods such as joystick or pedal controls are utilized in modern skid steers through which operators exercise movement as well as attachment use with accuracy.

Usually, there are also auxiliary circuits in the hydraulic system that give the operators the liberty to switch from one attachment to another without performance loss. The adoption of advanced technology like electro-hydraulic controls and load-sensing hydraulics has contributed a lot to the operation becoming easier, faster, and less tiring for the users.

Essentially, every action – from lifting to turning – is hydraulics and mechanics working together in harmony. It’s the machine’s responsiveness and speed that make it a must-have on dynamic job sites where time is very limited.

Different Types of Skid Steer Loaders

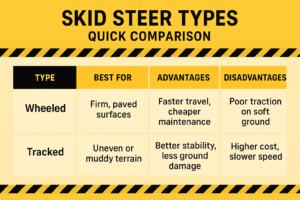

The first point to be aware of when considering a skid steer loader is that what you find on the market are generally two types of this machine-wheel and tracked skid steers with their respective strengths depending on the job site and nature of the ground. Knowing the difference helps you make a savvy purchase and lever the performance of each project.

Wheeled Skid Steers

Wheeled skid steers are mostly what you have in your mind when you think of the traditional kind of machines used on a construction site. Being fitted with four sturdy tires, they are perfect for hard, even surfaces like concrete, asphalt, or compacted soil. They are capable of achieving high travel speed, excellent maneuvering, and low initial cost compared to tracked models.

The list of their biggest advantages includes one-point mobility. The machines can be efficiently transferred from one job site to another without the need for surface protection thus they are perfect for urban construction or landscaping areas where ground protection is important. In addition, maintenance costs are comparatively low because tires are more easily and cheaply replaced than rubber tracks.

However, wheeled skid steers can struggle on soft, muddy, or uneven ground, where traction is limited. Moreover, tires can be worn out much faster if you excessively use wheeled skid steers on rough terrain, thus efficiency will decline. Nevertheless, if your projects are primarily carried out on solid surfaces, a wheeled skid steer will still be a cost-effective and dependable solution.

Tracked Skid Steers

On the contrary, tracked skid steers are the answer to problem terrains. Instead of tires, they are fitted with rubber tracks that offer better traction and flotation, thus they can move over mud, snow, and sand without sinking. This makes them very useful in landscaping, grading, and agricultural tasks when there is a need to protect the ground.

Although tracked skid steers usually cost more upfront and are more demanding in terms of maintenance, they have great versatility that compensates for these drawbacks. The tracks help in balancing the weight evenly and thus the ground pressure is released, and stability on the slopes or loose soil is improved. They are slower than the wheeled ones when working on hard ground, however, their off-road capability is way more than enough to make up for the speed disadvantage.

So, whether you are constructing a driveway, grading a hillside, or removing snow, the decision about whether to go with wheels or tracks depends on the location and manner of your skid steer loader usage.

Key Components of a Skid Steer Loader

The power and the versatility of a skid come from its key parts that are each playing the role of a working unit together in harmony with the rest of the components to shoulder the demanding jobs. Let us dissect the most important parts that make these small workhorses so efficient.

Engine

The engine, typically a diesel power unit with a range of 20 to 100 horsepower, is at the core of each skid steer. It is the major source of energy for the hydraulics and is, therefore, the main provider of the torque the operation such as lifting, digging, or hauling would need. Apart from offering better fuel efficiency, modern engines meet the most rigorous emission requirements without compromising power.

Lifting Arms

Lifting arms are the hardware that provides the machine with power. They are the parts that link the body and the attachments such as buckets or forks and thus, they are the elements that determine how far and how high the materials can be lifted. Skid steers either come with radial-lift or vertical-lift designs:

- Radial-lift arms allow more digging and grading reach at the middle of the height.

- Vertical-lift arms offer a higher lift and a longer reach and are, therefore, suitable for loading trucks or stacking materials.

Attachments

Attachments are what is turning the light of skid steers into the brightest. By employing a quick coupler system, operators are allowed to switch between a bucket, auger, grapple, or pallet forks within a few minutes. The machine thus, by daemonizing, becomes a multi-functional workhorse of chest for dozens of jobs.

Cab and Controls

The operator’s cab is, in the end, the place where comfort meets control. Today’s skid steers are furnished with closed, climate-regulated cabs fitted out with comfortable seats, touchscreen displays, and joystick controls which facilitate the precise handling. Some models may even come with the features such as ride control and backup cameras which add safety and diminish the fatigue experienced during long shifts.

The combination of components can be likened to a finely tuned orchestra that results in increased performance, great durability, and user-friendly operation. By knowing these components, you will be able to get the maximum out of the machine and also prevent unnecessary wear and costly breakdowns.

Popular Brands and Models in the Market

Brand reputation is of great importance when one is going to invest in a skid steer loader. There are a few manufacturers, who have established a legacy of reliability, durability, and progressive innovations in their products. Here are the leading brands that are today holding the market monopoly.

Bobcat

Bobcat is nearly synonymous with skid steers, as it’s the original innovator. Bobcat models like the S66 and T76 are recognized for their cutting-edge hydraulics, strong performance, and operator-friendly design. Their machines set the standard in the industry for versatility and dependability.

Caterpillar (CAT)

Power and durability are the main characteristics of Caterpillar skid steers. Construction site, where the heavy-duty machines such as the CAT 262D3 and CAT 289D3 would be put to use, will be the places where their performance will be unmatched. Favorable for their smooth controls, high lift capacity, and build-quality, CAT machines have been at the forefront of the market.

John Deere

By combining comfort with technology, John Deere presents a range of skid steers that are a cut above the rest. With features such as EH joystick controls and DozerMode, the John Deere 332G model provides not only accuracy but also great power thus, it becomes the best choice for large-scale projects.

Case Construction

Case skid steers features the SR270B for instance, are recognized for their solid construction and going through the routine maintenance work without any trouble. They provide good visibility and comfort for the operator at the same time impressive lifting power and hydraulic performance remain their traits.

Every brand has something different to offer—from Bobcat’s heritage, Caterpillar’s strength, and John Deere’s innovation—so the decision of which one to go for depends on your priorities, like comfort, price, or state-of-the-art technology.

Top Attachments That Maximize Productivity

One of the main reasons which make the skid steer loaders a favorite among contractors and operators worldwide is the possibility to change the tool with the attachment. Simply by changing the tool, these small machines are able to execute hundreds of different tasks thus, saving hours, money, and human power. Below there is an explanation of some of the most used and productivity-increasing attachments which are available nowadays.

Bucket

The bucket is the most frequent and adaptable attachment. It is an absolute must for any operation that involves digging, loading, grading, or carrying of materials like soil, gravel, and debris. Buckets exist in different versions—general-purpose, 4-in-1, and rock buckets, each being designed for a specific function.

For example, a 4-in-1 bucket can open and close hydraulically which means that it can do the tasks of gripping, dozing, and spreading material, thus, functioning as a multipurpose tool.

If setting the ground straight for a driveway or transporting compost is what you are up to, the bucket is the perfect tool. Quite often it is the first attachment that new operators try and it continues to be a tool that is indispensable in all sectors.

Auger

How about perfect holes for fence posts, trees, or foundations? The answer to your needs is surely the auger attachment. The hydraulic motor that powers it is capable of drilling in soil, clay, or even in frozen ground without difficulty. The sizes of auger bits vary thus, depth and diameter can be controlled very accurately.

This attachment finds itself in those three sectors: landscaping, agriculture, and construction, solely due to the demand for constant hole sizes. Moreover changing auger bits takes only a few minutes thus, giving you more flexibility in your workday.

Grapple

The grapple attachment equips your skid steer with the ability to grip powerfully. It is meant for the collection of materials that have an irregular shape such as logs, rocks, scrap metal, or demolition debris. The two claws operated by hydraulics that open and close provide a very firm grip on large and heavy stuff thus, there is no risk of falling out.

You can find grapples in projects related to the forestry and recycling industries, as well as in demolition works, where both precision and power are necessary. They free up the operator from manual handling which significantly increases the safety and productivity levels.

Pallet Forks

Pallet forks are considered a necessity in the warehousing, agriculture, and material handling areas of business. By converting your skid steer you get a small forklift, which in turn is perfect for loading and unloading pallets, hay bales, and heavy crates. The adjustment of the tines enables easy handling of different pallet sizes and, because of the fact that skid steers are more compact than forklifts, they can work efficiently even in the tightest of spaces.

Bonus Attachments Worth Mentioning

Besides these four, the list of attachments goes on with trenchers, snow blowers, brush cutters, and brooms, which further extend the capabilities of a skid steer. Thanks to quick-attach systems, changing between them is almost effortless—hence, productivity reaches a completely new level.

Applications of Skid Steer Loaders in Different Industries

Without a doubt, skid steer loaders are the perfect examples of multi-tools as they can be easily found working in almost all industries. Thanks to their versatility, power, and compact design, they have become the must-have machines for people who are willing to work efficiently and be adaptable. We can examine the use of the massive machines by different industries to see the extent of their power.

Construction

Skid steers are a must-have in the field of construction. They take on the tasks such as the preparation of the site, excavation, grading, clean-up of the site, and the transportation of materials swiftly and easily.

Among the various tasks that could be entrusted to them, contractors make use of the machines for the loading of trucks, the moving of gravel, and even the drilling of foundations. Due to their diminutive size, they are perfect for the performance of work in enclosed spaces, such as urban construction sites where larger machines cannot make it.

Their ability to change their attachments rapidly is what makes them so valuable. One moment a skid steer might be digging a trench, then at the next, it could be filling the trench or leveling the soil—all without the need to change the machine. Such flexibility is liked by all project managers as it not only saves time but also the money.

Agriculture

Skid steers are just like a pair of super-strong extra hands for farm work. Moving feed, cleaning the barns, transporting hay bales, and even digging irrigation channels are some of their uses. By using inventions such as bale spears, manure scrapers, and augers they speed up the everyday operations and at the same time reduce the hard manual work to a great extent.

Farmers especially like their maneuverability in small barns or stalls, where tractors might be too big to work effectively. A good skid steer is capable of doing the same work as several pieces of equipment, thus, it becomes an essential investment for increased agricultural productivity.

Landscaping

Accuracy and versatility are the main requirements in landscaping, and that is exactly where the strength of skid steers lies. Whether it is soil grading, sod transporting, mulch spreading, or pond digging, they are capable of handling all the stages of a landscaping project. The operators usually use such attachments as land levelers, soil conditioners, and brush cutters to make the lawns and gardens perfectly finished.

The compact size of the devices makes them suited for residential projects as they can easily pass through narrow gates or driveways without causing any damage to the areas around. They are the real heroes behind the perfectly leveled yards and smoothly contoured gardens that you see in professional landscaping projects.

Snow Removal

Once winter is here, skid steers take up the roles of snow removal machines. Outfitted with snow blowers, blades, or pushers, they can clear parking lots, sidewalks, and roads in no time. The operators are comfortable, even in freezing conditions, due to the heated cabs, and the snow removal is done quickly and easily, thanks to the hydraulic power, albeit the snow is dense or frozen solid.

Skid steers are the main snow removal tools, which city maintenance crews, as well as small business owners, depend upon, to keep the operations going during the harsh winters.

Other Uses

Moreover, skid steers could also be spotted in the mining, waste management, and forestry sectors and even in disaster recovery. What makes them so versatile is their title “jack of all trades” that they hold in every sector, where heavy lifting and precision within a small area are required.

Advantages of Using a Skid Steer Loader

What you will hear from a seasoned contractor or farmer if you ask them about the reasons why…

1. Versatility

The most appealing feature of a skid steer is its versatility. It has a hundred combinations of compatible attachments, with which any base machine can perform such activities as digging, lifting, grading, sweeping, plowing, and more, i.e., work can be done by only one machine, thus avoiding the need of buying three or more different pieces of equipment.

2. Compact Size and Maneuverability

Skid steers are specifically made for places with a small area of work. Their zero-radius turning ability lets them turn within their own shadow. This feature makes them perfect for urban construction, interior demolition, or small-acre farming where the available space is limited. Although they are small in terms of size, their hydro…

3. Efficiency and Time-Saving

Time is money, especially in construction. Skid steers raise the level of productivity by doing very quick changes of the attachments combined with the fast changing of the tasks. In addition to this, the machines are able to operate at a high traveling speed and, thanks to their lightweight and hydro…

4. Low Operating Costs

Compared to bigger loaders or excavators, skid steers are more fuel-efficient and require less maintenance. Parts are easily obtainable, and a lot of the components are built for effortless servicing, thus, the time for the machine to be off work is kept to a minimum, and so are the repair expenses.

5. Accessibility

Even small business entrepreneurs or homeowners are in a position to rent or buy compact skid steers at reasonable prices. The machines feature user-friendly controls, which make them easy to work with even if you are a beginner, and at the same time,

Limitations and Challenges of Skid Steer Loaders

Skid steer loaders are very versatile and efficient, however, they are not perfect. Like any other heavy-duty machines, these come with limitations and challenges, which the users should be aware of in order to get the maximum performance and least downtime possible. Knowing these drawbacks will help operators to be more careful and safer.

Maintenance Costs

Among the most serious issues related to a skid steer loader is the problem of maintenance. The that means the machine needs frequent servicing of the parts that are more prone to wear if the upkeep is not done properly, there could be hydraulic leaks, engine wear, and electrica for tracked models, only replacing the track can be quite costly.

Operator Safety Risks

Another point where a limitation can be found is in operator safety. Due to the fact that skid steer proper training and safety measures are the only ways to reduce the danger.

Ground Impact Issues

Especially wheeled skid steers are known for ground compaction as well as surface damage. If tracked skid steers, however, solve this problem by spreading the weight evenly over the surface

Project Type

First point is to consider what type of work will be the primary ones to be done.

- While performing a project which includes digging, grading, or heavy lifting, a model with high hp and lift capacity would be the right choice.

- For the needs of landscaping, farming, or light construction, a compact skid steer with moderate power will fit the job perfectly.

- In case your work will consist of indoor demolition or tight spaces, better maneuverability can be achieved by a smaller, narrow-frame model.

Load Capacity

Rated operating capacity (ROC) is the factor that tells the maximum weight a skid steer can be

- Light-duty models: ROC under 1,500 lbs

- Mid-size models: ROC between 1,500–2,200 lbs

- Heavy-duty models: ROC above 2,200 lbs

Terrain Conditions

The surface of the worksite is also a major factor in making a decision:

- Wheeled skid steers are more suitable for rock or paved surfaces as they offer better speed

- Tracked skid steers provide more traction and flotation and thus are decidedly better

In case your job locations will be mixed, some operators decide to have over-the-tire tracks

Safety Tips for Operating a Skid Steer Loader

Besides being very beneficial, the operation of a skid steer loader is a serious responsible due to the small size and power of these machines, it means that even a minor mistake can do

Safety should always be at the forefront—whether you are an experienced operator or a new base essential safety tips that should be observed by every operator we going to review are here.

Operator Training

Safe operation fundamentally rests on the operator’s training. Before operating any equipment .Training courses teach skills that are core: load balancing, hydraulic control, and attachments etc.

Proper Load Handling

Skid steers are intended to be stable structures, but only when the loads are handled properly

- While on the move, lower the bucket or attachment to keep the center of gravity low.

- Do not make a sudden turn while carrying a load that is raised—you’re greatly increasing the risk

- Never go beyond the rated operating capacity (ROC).

- Before lifting or transporting, make sure that loads are secured properly.

While on sloping grounds, it is advisable to move with the heavy part of the machine

Use of Safety Gear

One thing that must be strictly followed—the usage of personal protective equipment (PPE)

- Hard hats and steel-toed boots

- High-visibility vests

- Safety goggles and gloves

- Hearing protection (since skid steers can be quite loud)

Also, it is good practice to always wear a seat belt and check that the safety bar or inter

Site Awareness

Due to the compactness of a skid steer, the view at the back is limited, hence, you need to Check blind spots always and in case you have mirrors or a backup camera, use them. When do not allow any person to stand on or near the attachments. An accident that results fro…

Conclusion

The skid steer loader is not just a mere piece of hardware—it is a revolution in the field the very machine is small yet formidable and over the years it has proven the concept that where to? The answer is the continuous evolution of technologies which are turning skid steer .Anyway, putting one on your worksite is the next best thing after seeing what it really does